LSR is the abbreviation for Liquid Silicone Rubbers. LSR is molded with a Liquid Injection Molding System (LIMS), a molding system for liquid material. We make the most of the system and offer a wide variety of silicone products with different features from complex shapes to high hardness and transparency. The use of LSR (liquid silicone rubber and resin) in the system offers the following advantages.

The use of LSR (liquid silicone rubber and resin) in the system offers the following advantages.

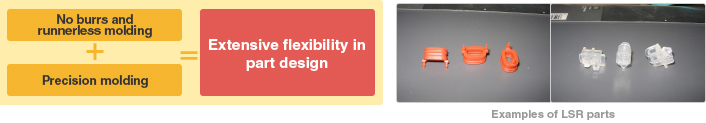

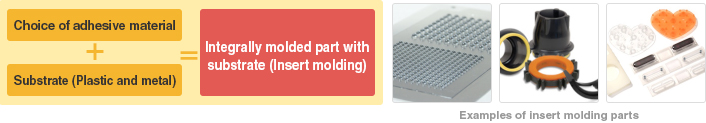

The use of LSR (liquid silicone rubber and resin) in the system offers the following advantages.

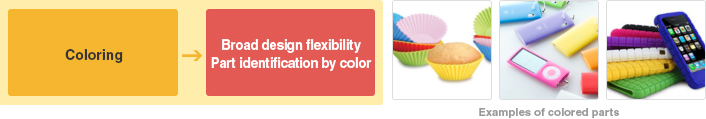

LSR materials offer excellent properties including heat resistance, electrical insulation, high strength, flame retardancy and conductivity. They are not only molded into transparent parts but colored easily after molding.

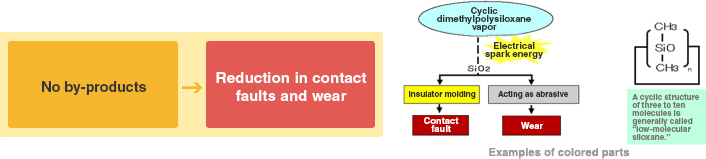

LSR material generates no by-products from curing.

We are jointly developing the LSR business in a project with Kisco Ltd.

Please contact KISCO LTD. to learn about ordering silicon molded parts.